1. Multi-effect tubular evaporator

Equipment principle

Equipment principle

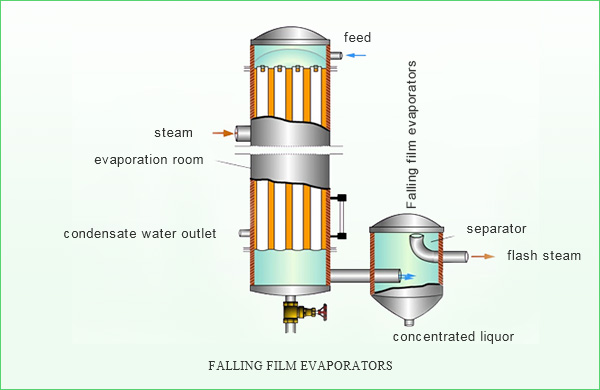

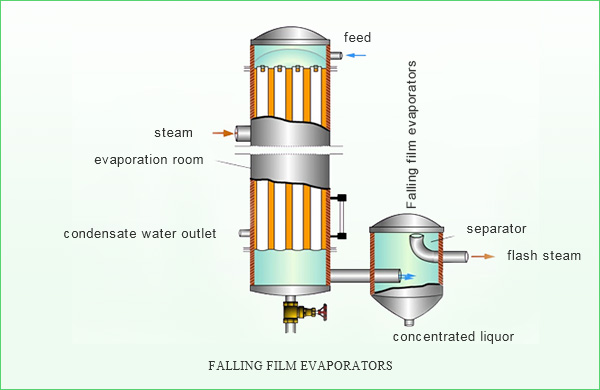

It is mainly composed of a plurality of heating chambers and separation chambers. There are several tubes in heating chambers. Falling film evaporators are widely used to evaporate and concentrate the feed liquid. Under the action of gravity, the feed liquid flows into the heating tubes from the top through the liquid distributor. The feed liquid forms films along the inner wall to be evaporated. In order to form a film-like downflow, a liquid distribution device needs to be designed when feeding.

Equipment features

Advantages:

Advantages:

1. The tubes are not easy to be blocked and suitable for high concentration materials.

2. It is suitable for evaporation of heat-sensitive materials because of short one-way residence time.

3. The effective temperature difference is large and the product concentration is high.

4. It is energy saving, low steam consumption and low cooling water used to cycle.

5. High degree of automation is conducive to the construction and transformation of intelligent workshops.

6. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Disadvantages:

Disadvantages:

1. The heat transfer coefficient is smaller than the rising film evaporator.

2. he height of the tubes is high, which is not suitable for small-scale factories.

3. It is quite sensitive to the fluctuation of the feed liquid, which requires standardized design and thoughtful consideration.

Application

Application

The multi-effect tubular evaporator used in glucose, fructose and maltose

The multi-effect tubular evaporator is widely used in the fields as follows.

The multi-effect tubular evaporator is widely used in the fields as follows.

-Sugar industry

starch sugar, including glucose, dextrose monohydrate, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

Organic acids include L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

-Pharmaceutical industry

antibiotics, etc.

-Thermoelectric industry

water treatment, etc.